Welcome to our comprehensive guide on types of electric heaters for industrial use in Kapiti. Whether you’re managing a manufacturing plant, warehouse, or commercial space, finding the right heating solution is crucial for comfort, efficiency, and safety. Here, you’ll discover detailed insights into various industrial electric heaters, their applications, and key considerations tailored to Kapiti’s unique environment. Our goal is to help you make informed decisions that meet your specific needs while optimizing energy use and reducing costs. Let’s explore the best heating options for your industrial facility together.

Table of Contents

Key Takeaways

- Different electric heater types suit different Kapiti industrial applications, from warehouses and food processing plants to workshops and marine-related facilities in Paraparaumu, Waikanae, and Otaki.

- Common options include fan-forced space heaters, infrared and radiant heaters, duct heaters, immersion and circulation heaters, and process heaters for tanks and pipework.

- Kapiti’s coastal climate, humidity, and salt air mean corrosion-resistant construction, IP-rated enclosures, and correct electrical design are essential for longevity and safe operation.

- Working with qualified electricians ensures correct sizing, three-phase compatibility, and full compliance with New Zealand electrical and safety standards.

- This guide will help facilities managers, factory owners, and maintenance teams compare industrial electric heater types and choose what fits their site, specific needs, and budget.

Understanding Industrial Electric Heating in Kapiti

Electric heating has become the backbone of temperature control across Kapiti’s industrial sector. With reliable grid power, zero combustion fumes at the point of use, and superior control and zoning capabilities, electric systems offer a practical solution for facilities that need consistent, safe heating without the complications of fuel storage or complex venting requirements.

Industrial vs Domestic Heaters: Key Differences

The heating appliance you might use to keep your entire home warm bears little resemblance to what’s required in a commercial space or factory floor. Industrial electric heaters differ from domestic units in several critical ways:

| Feature | Domestic Heaters | Industrial Heaters |

|---|---|---|

| Power Output | 1-3 kW typical | 3-60+ kW |

| Power Supply | Single-phase 230V | Often three-phase 400V |

| Duty Cycle | Intermittent use | Continuous operation |

| Construction | Lightweight plastic/sheet metal | Heavy-gauge steel, industrial components |

| Safety Rating | Basic IP ratings | Higher IP ratings for dust/moisture |

| Control Systems | Simple thermostat | Advanced controllers, BMS integration |

Typical Kapiti Industrial Settings

The range of facilities requiring industrial heating across the Kapiti Coast is broader than many realise:

- Manufacturing plants in Paraparaumu and Otaki

- Logistics warehouses and distribution centres

- Cool-store loading areas requiring temperature maintenance

- Food and beverage processing facilities

- Small engineering workshops and fabrication shops

- Coastal marine facilities and boat-building operations

Electric vs Gas and Diesel Heating

When comparing electric heating against gas or diesel alternatives in commercial buildings, several factors come into play:

Advantages of electric systems:

- Zero onsite emissions, improving air quality for workers

- Simpler installation without flue or venting requirements

- Precise temperature control down to individual zones

- Lower maintenance overhead with no combustion components

- Enhanced safety with no fuel storage or gas lines

Considerations:

- Energy costs per kWh may be higher than some fuel alternatives

- Large installations require adequate electrical capacity

- Three-phase supply essential for higher-output units

New Zealand’s electrical standards, particularly AS/NZS 3000 (the Wiring Rules) and related regulations, govern all industrial heater installation. This makes professional design and qualified installers mandatory for most fixed industrial heating systems.

Major Types of Electric Heaters for Industrial Use

Before diving into specifics, here’s an overview of the main heater families you’ll encounter when sourcing equipment for Kapiti industrial premises.

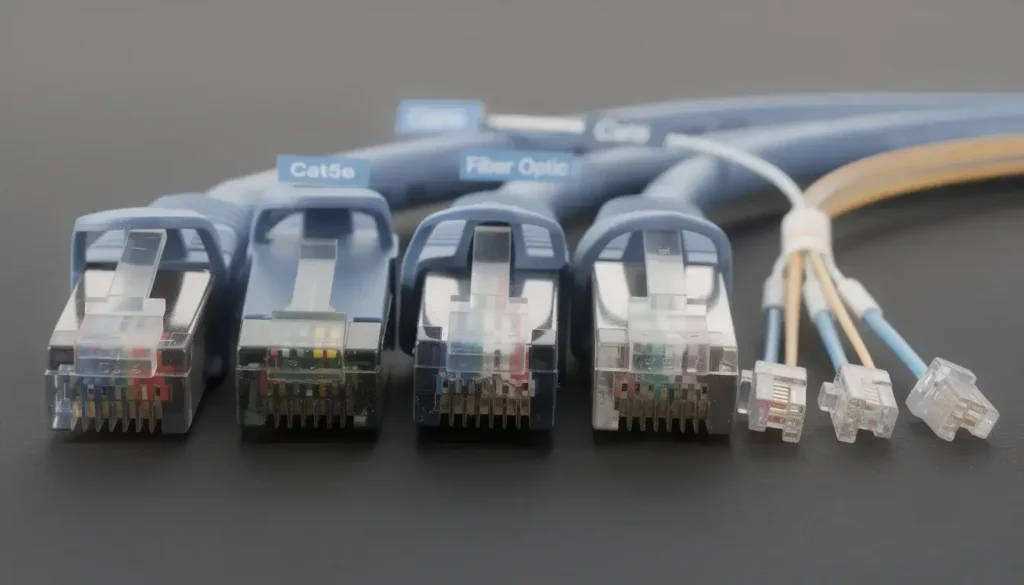

Core heater categories:

- Fan-forced space heaters – Heat and circulate air in enclosed indoor areas

- Infrared and radiant heaters – Directly warm people and objects without heating all ambient air

- Duct and inline heaters – Integrate with ventilation systems for whole-area or ducted systems heating

- Immersion and circulation heaters – Heat liquids directly in tanks, vessels, or process lines

- Band and cartridge heaters – Provide localised heat on machinery, moulds, and process equipment

- Specialised process heaters – Including flexible jackets, trace heating, and platen heaters

Most medium to large units in industrial settings will be three-phase (typically 8-60 kW and above), while smaller portable or task heaters may run on single-phase supply. The following sections explain the pros, cons, and ideal use cases for each type so you can shortlist options before consulting an electrician or engineer.

Fan-Forced Industrial Space Heaters

Fan-forced electric heaters combine heating elements with an internal fan to generate warm air movement throughout larger indoor areas. The fan draws cool air across the elements and pushes heated air into the space, creating circulation that helps maintain even temperature distribution.

Common Kapiti Applications

- Warehouse picking zones in Paraparaumu industrial estates

- Small manufacturing bays and assembly areas

- Engineering workshops and maintenance facilities

- Temporary heating during construction or fit-out projects

- Staff break rooms and locker areas in larger facilities

Design Features

Quality industrial fan heaters share several characteristics:

- Robust steel housings with powder-coated or galvanised finishes

- Wall-mounting or ceiling-mounting options for floor space efficiency

- Adjustable thermostats and often multi-stage heating

- Power outputs ranging from 3 kW to 30 kW

- Three-phase power compatibility for larger models

- Thermal cut-out protection for safe operation

Advantages

Fan-forced heaters offer efficient heating with relatively quick warm-up times. The forced air movement creates good mixing throughout the space, preventing hot spots and cold zones. Installation is straightforward in non-hazardous areas, and units can be relocated if facility layouts change.

Limitations

These heaters can stir up dust and particulates, making them less suitable for clean environments. They’re also less efficient in spaces with very high ceiling height or poor insulation, where the heated air simply rises and stratifies. Larger units require dedicated circuits and may necessitate switchboard capacity upgrades.

Infrared and Radiant Electric Heaters

Unlike convective systems, infrared and radiant heaters warm people and objects directly through electromagnetic radiation rather than heating all the air in a space. This principle of transferring heat through radiation makes them highly efficient for specific applications.

Kapiti Industrial and Commercial Applications

- Spot heating for individual workstations on factory floors

- Loading docks exposed to constant door opening

- Open-front workshops and semi-enclosed bays

- Outdoor or semi-outdoor areas subject to coastal winds

- Areas where maintaining full ambient temperature is impractical

Main Styles

| Type | Description | Best For |

|---|---|---|

| Overhead radiant panels | Flat panel units mounted at ceiling level | Offices, light industrial |

| Quartz/halogen tube heaters | Glass tube elements with rapid warm-up | Spot heating, loading docks |

| High-intensity radiant units | Powerful units for high mounting heights | Warehouses, large open areas |

Benefits

Radiant heaters excel in draughty or partially open areas where heating the air would be futile—the warmth reaches workers directly. They provide fast perceived warmth within seconds of switching on, operate quietly without fans, and allow precise zoning to specific benches or process lines. This can help save energy compared to heating entire volumes unnecessarily.

Key Considerations

Correct mounting height and clearance from combustible materials is essential. Some tube heaters produce visible light that may cause glare. For Kapiti’s salty coastal air, corrosion-resistant fittings and housings are critical to extend service life and maintain performance.

Duct, Inline and Air Handling Electric Heaters

These heaters install inside or adjacent to ductwork and air handling systems, heating large volumes of air as it moves through the system. They integrate with existing HVAC infrastructure for whole-building or zone-based heating.

Typical Kapiti Uses

- HVAC systems serving offices attached to manufacturing facilities

- Clean rooms and controlled environments

- Light manufacturing floors requiring filtered, heated air

- Ventilation pre-heating for make-up or fresh air systems

- Central heating distribution throughout larger commercial buildings

Common Configurations

- Rectangular duct heaters – Fit into standard rectangular ductwork

- Circular inline heaters – Install within round spiral duct runs

- Heater banks – Integrated with existing air handling units for larger capacity

Advantages

Duct heaters provide even whole-area heating with minimal visible equipment in the occupied space. They integrate with existing ventilation, filters, and building management or smart system controls. Air quality benefits from the filtration that occurs as air passes through the handling unit.

Design Points

Correct sizing requires calculating the airflow rate and target temperature rise. Pressure drop across the heater elements must be factored into fan capacity. Over-temperature protection is mandatory, and installation should only be undertaken by commercial HVAC and electrical specialists who understand the system integration requirements.

Immersion and Circulation Heaters for Liquids

Immersion and circulation heaters are purpose-designed for heating liquids—water, oils, cleaning solutions, food-grade fluids, and various process chemicals. These systems can achieve 100% energy efficiency by converting all electrical input directly to heat within the liquid.

Common Kapiti Applications

- Hot water storage for hygienic wash-down in food processing

- Dairy processing and beverage production vessels

- CIP (clean-in-place) tanks and sanitisation systems

- Chemical dosing and treatment tanks

- Process baths in engineering workshops

- Frost protection for outdoor water systems

Immersion Heaters

Direct immersion heaters insert into tanks or cylinders through a mounting boss. The heating element is fully submerged, transferring heat directly to the liquid. Sheathed elements come in various materials matched to the fluid type:

- Copper – General-purpose water heating

- Stainless steel – Corrosive liquids and food-grade applications

- Titanium – Highly aggressive chemicals and salt water

- Incoloy – High-temperature oils and demanding environments

Flanged immersion heaters weld horizontal elements to a flange for side-mounting on larger vessels and can reach temperatures up to 649°C (1200°F) for industrial processes.

Circulation Heaters

Circulation heaters use an external vessel containing the heating elements. Pumps move the liquid through the heater and back to the main tank or process. This configuration offers:

- Better temperature control and uniformity

- Easier maintenance access without draining tanks

- Enhanced safety with corrosive or viscous fluids

- Reduced risk of localised overheating

Safety and Design Issues

Critical factors for these systems include:

- Material compatibility between sheath and process fluid

- Thermostat and high-limit safety controls

- Level sensors to prevent dry-firing (which destroys elements)

- Compliance with food safety, process, and hygiene standards where applicable

- Appropriate IP ratings for the installation environment

Band, Cartridge and Process Heaters for Machinery

This category focuses on smaller but critical heater types used directly on machinery and production lines rather than for general space or room heating. They’re essential components in many manufacturing processes.

Band Heaters

Band heaters clamp around cylindrical surfaces—barrels, pipes, nozzles, and drums. Common applications include:

- Plastics extruder barrels in injection moulding

- Drums containing materials that must maintain temperature

- Process lines where pipe contents need heating

- Die heads and other cylindrical tooling

These units deliver uniform surface heating through direct conduction, with temperature capabilities varying by construction type.

Cartridge Heaters

Cartridge heaters are cylindrical elements inserted into drilled holes in metal blocks, moulds, dies, or other tooling. They provide:

- Precise localised heating up to approximately 427°C (800°F)

- High power density in compact form factors

- Even heat distribution in platens and blocks

- Long service life when sized correctly

Available in both imperial and metric sizes, these are critical components in plastics processing, packaging machinery, and precision manufacturing.

Other Process Heaters

| Type | Application |

|---|---|

| Flexible heating jackets | Conform to irregular shapes, drums, IBC containers |

| Trace heating cables | Maintain temperature in long pipe runs |

| Platen/plate heaters | Presses, curing applications, composite manufacturing |

| Rope and band heaters | Beakers, pipes, laboratory equipment |

Selection Factors

Key considerations for machinery heaters include:

- Operating temperature range required

- Power density (watts per square centimetre)

- Control method—simple thermostats vs PID controllers

- Replacement access for maintenance

- Quality of wiring and terminations for continuous duty

- Compressor and other equipment compatibility where relevant

Choosing the Right Electric Heater Type for Your Kapiti Facility

Selecting the best system for your operation depends fundamentally on what you’re heating: people and ambient air, specific workstations, liquids in tanks, or process equipment on production lines. Getting this right affects both your energy consumption and operational effectiveness.

Key Assessment Factors

Before engaging suppliers or electricians, document these aspects of your facility:

Physical characteristics:

- Floor area and ceiling height of spaces requiring heating

- Current insulation quality in walls, roof, and doors

- Level of draught or frequency of door opening

- Number and type of outdoor units or openings

Operational requirements:

- Occupancy patterns and shift schedules

- Process temperature requirements for any equipment or materials

- Whether you need heating year round or seasonally

- Cooling mode requirements if relevant

Existing infrastructure:

- Current electrical supply (single or three-phase)

- Switchboard capacity and condition

- Existing HVAC or ventilation systems

- Any building management system in place

Kapiti-Specific Considerations

The coastal location of Kapiti presents unique challenges:

- Corrosion resistance – Salt-laden air accelerates corrosion of exposed metals. Stainless steel housings and appropriate surface treatments are essential.

- High winter humidity – Moisture ingress can damage electrical components. Appropriate IP ratings (typically IP54 or higher) protect against this.

- Wind exposure – Semi-outdoor and open-bay areas face significant heat loss. Radiant systems often outperform convective options in these settings.

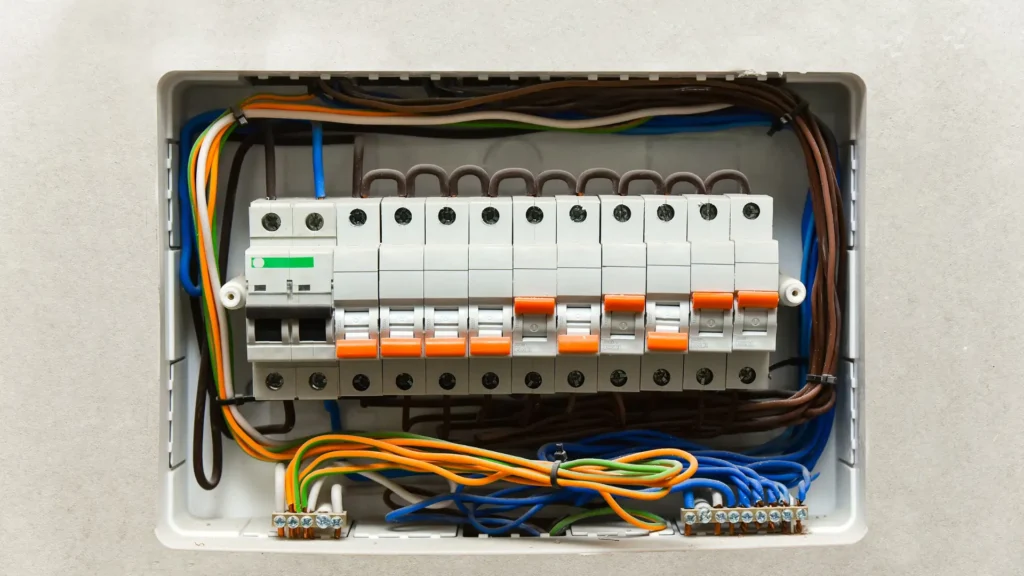

Electrical Supply Considerations

Higher-output industrial heaters demand careful electrical planning:

- Confirm availability of three-phase power at required capacity

- Assess existing switchboard for spare ways and total capacity

- Plan dedicated circuits with appropriate protection devices

- Consider energy bills impact of different sizing options

- Factor in any power factor correction requirements

Document your loads, constraints, target temperatures, operating hours, zoning needs, and safety requirements before seeking detailed designs. This preparation allows electricians and engineers to provide accurate sizing and realistic cost estimates.

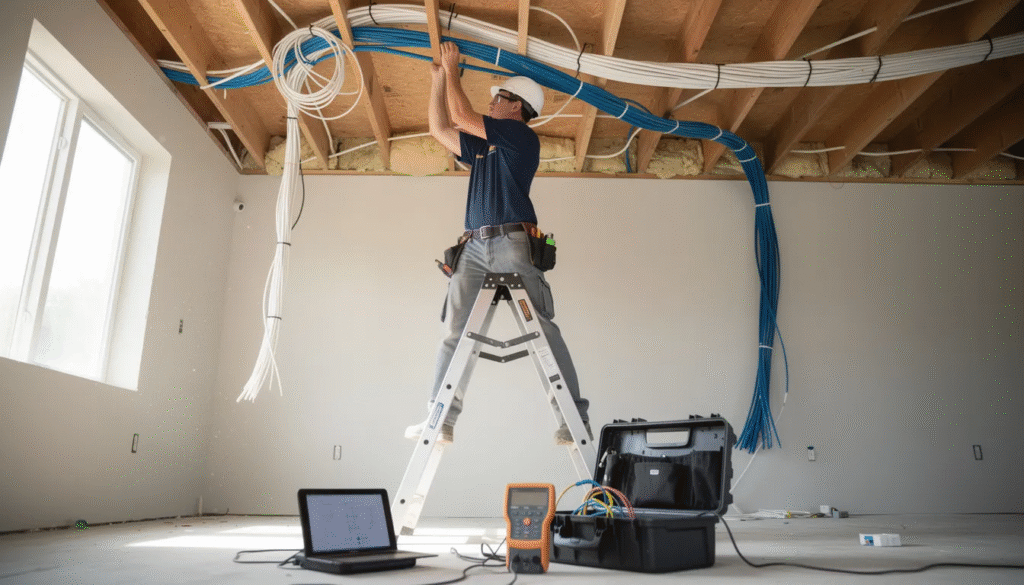

Installation, Safety and Compliance Considerations

Industrial electric heaters must be installed and commissioned by qualified professionals under New Zealand’s regulatory framework. The electrical work involved requires registration and licensing, and incorrect installation creates serious safety risks.

Core Safety Topics

Electrical requirements:

- Correct cable sizing for the load and installation method

- Appropriate protection devices (MCBs, RCDs as required)

- Proper earthing and bonding

- Thermal cut-outs and over-temperature protection integral to equipment

Physical installation:

- Safe mounting clearances from combustible materials

- Appropriate IP ratings for the installation environment

- Access for maintenance and inspection

- Protection from physical damage in busy work areas

Environmental and Area Classification

Not all heaters suit all environments:

| Environment | Requirements |

|---|---|

| Wet wash-down areas | High IP rating (IP65+), sealed enclosures |

| Corrosive atmospheres | Resistant materials, sealed controls |

| Dusty environments | Appropriate ingress protection, cleanable |

| Hazardous zones | Specialist equipment, ATEX/IECEx certification |

Avoid installing standard equipment where vapours, combustible dusts, or other hazards may be present without proper engineering assessment.

Maintenance Requirements

Regular maintenance preserves both safety and efficiency:

- Scheduled inspections for damage, corrosion, and ice build up (outdoor units)

- Testing of thermal safety devices and thermostats

- Cleaning of fans, filters, and heat exchange surfaces

- Verification of control systems and temperature calibration

- Checking of electrical connections for tightness and condition

- Defrost mode functionality testing where applicable

Documentation

Maintain proper records to support compliance, insurance, and operational continuity:

- Commissioning records and test certificates

- Operating instructions accessible to staff

- Maintenance schedules and service history

- Equipment specifications and wiring diagrams

- Risk assessments for the installation

Frequently Asked Questions about Industrial Electric Heaters in Kapiti

Are electric heaters cost-effective for large industrial buildings on the Kapiti Coast?

While electricity unit cost can be higher than some fuels, electric heaters offer precise control that prevents waste, zero onsite emissions, lower servicing requirements, and no fuel storage costs. Multi-zone control allows you to heat only occupied areas, night setback reduces energy use during unoccupied periods, and good insulation maximises efficiency. For many Kapiti operations, the total cost of ownership competes favourably with combustion alternatives when maintenance, compliance, and carbon footprint considerations are included.

Can I use the same type of electric heater in both office and factory areas?

Generally, no. Office areas typically use ducted HVAC, packaged units, or smaller panel heaters designed for quiet, clean operation. Factory floors require more robust, higher-output units—often three-phase—designed to handle dust, vibration, and demanding duty cycles. Match your heater type to the environment’s noise tolerance, dust levels, and physical demands. A qualified installer can specify appropriate equipment for each zone.

What size (kW) industrial heater do I need for my warehouse?

Sizing depends on multiple factors: building volume, insulation quality, air changes per hour, target temperature, external conditions, and usage patterns. Rule-of-thumb calculations often underestimate requirements or lead to oversizing. Have a qualified designer or electrician perform a proper heat-loss calculation considering Kapiti’s specific climate conditions. This ensures you don’t pay for unnecessary capacity while maintaining adequate heating.

How long do industrial electric heaters typically last in a coastal area like Kapiti?

With corrosion-resistant construction, correct installation, and regular maintenance, lifespans of 8-15 years are common for quality industrial electric heaters. Harsh wash-down environments or direct marine exposure may shorten this unless equipment is specifically rated for such conditions. Investing in appropriate materials (stainless steel housings, sealed controls) and maintaining a regular inspection schedule extends service life significantly.

Can existing single-phase wiring support new industrial electric heaters?

Small portable heaters (up to about 2-3 kW) may run from standard single-phase circuits, but most fixed industrial units need dedicated circuits, often with three-phase supply for larger outputs. Adding significant new electrical loads requires assessment of your switchboard capacity, incoming supply, and protection arrangements. Have an electrician check your installation before purchasing equipment to avoid costly surprises. You may need a new heat pump sized correctly for larger spaces or heat pump installation for certain applications.

How do industrial electric heaters compare to heat pumps for Kapiti industrial applications?

Heat pumps, including air source heat pumps and ground source heat pumps, offer highly efficient heating by transferring heat from outside air or the ground rather than generating it directly. The heat pump cost can be higher initially, but running costs are typically lower due to superior energy efficiency. However, heat pumps work best for space heating at moderate temperatures and may not suit high-temperature process applications. For ambient heating of commercial settings, consider getting a size heat pump calculation done. Remember that any heat pump serviced regularly will maintain its efficiency longer. The best system depends on your heating needs, whether you need hot water integration, and the indoor unit and outdoor unit placement options available.

What qualifications should installers have for industrial heating work?

All fixed electrical work must be performed by qualified electricians registered with the Electrical Workers Registration Board (EWRB). For more complex installations involving HVAC integration, geothermal systems, or process heating, look for contractors with specific industrial experience and familiarity with relevant standards. Quality installation by qualified installers ensures safety, compliance, and reliable operation of your heating investment.

What are industrial heat pumps used for?

Industrial heat pumps are used to provide energy-efficient heating and cooling for large commercial and industrial sites such as warehouses, factories, and processing facilities.

Why are heat pumps more energy efficient than electric heaters?

Heat pumps move heat rather than create it, typically using 1kW of electricity to generate up to 4kW of heat, making them up to four times more efficient than traditional electric heaters.

Do heat pumps work for both heating and cooling?

Yes. Heat pumps provide both heating in winter and cooling in summer, helping businesses reduce overall energy consumption and utility costs.

How long does an industrial heat pump last?

With proper installation and maintenance, a heat pump typically lasts 15–20 years.

How often should a heat pump be serviced?

Professional heat pump servicing is recommended once a year to maintain efficiency, prevent breakdowns, and extend lifespan.

What happens if a heat pump is installed incorrectly?

Improper heat pump installation can lead to reduced efficiency, higher energy bills, frequent faults, and costly repairs.

Who is legally allowed to install heat pumps in New Zealand?

All electrical installations in New Zealand must be carried out by licensed electricians and comply with national electrical safety standards.

What regulations apply to industrial heating in New Zealand?

New Zealand has a National Policy Statement and National Environmental Standards governing greenhouse gas emissions from industrial process heat.

What are electric fan heaters best used for?

Electric fan heaters are ideal for quick, uniform heat distribution in workshops, garages, construction sites, and small-to-medium commercial spaces.

Are electric fan heaters suitable for drying buildings?

Yes. Electric fan heaters deliver instant forced-air heat, making them highly effective for drying construction materials and damp buildings.

What power ratings do industrial fan heaters come in?

Industrial electric fan heaters typically range from 3kW to 45kW, with 3-phase models available for high-demand environments.

What size fan heater is best for small areas?

Portable single-phase fan heaters (2.4kW–3kW) are commonly used for localized heating tasks.

Are portable industrial fan heaters available for hire?

Yes. Portable electric fan heaters from 2.4kW up to 45kW can be rented for temporary heating or drying applications.

What are radiant heaters used for?

Radiant heaters are effective for quickly heating large areas, commonly used in warehouses and factories.

Why are infrared heaters good for high-ceiling spaces?

Infrared heaters heat people and objects directly, rather than the air, making them ideal for high-ceiling or drafty environments.

What is the difference between convection and infrared heating?

- Convection heaters warm the air, which then circulates through the space

- Infrared heaters provide direct heat to objects and people

Both are widely used in industrial applications.

What are band and strip heaters used for?

Band and strip heaters wrap around pipes, barrels, or tanks and are commonly used in plastic extrusion, drum warming, and industrial processing.

What are circulation heaters used for?

Circulation heaters heat fluids or gases as they flow through a closed system and are commonly used in petrochemical and industrial processing.

What are immersion heaters used for?

Immersion heaters heat liquids, oils, or gases in tanks and are available in flanged, screw plug, and over-the-side designs, including heavy-duty options for corrosive environments.

What heaters are used in large warehouses or sheds?

Large warehouses typically use 3-phase, 415V electric heaters, such as 9kW–30kW electric space heaters or industrial unit heaters.

What are electric unit heaters?

Electric unit heaters provide consistent, safe heating in large workshops and factories, improving worker comfort and productivity.

Are there heaters designed for workstations in large spaces?

Yes. Models like the Herschel Power 8 (6.4kW) provide targeted infrared heat for workstations, loading bays, and open industrial areas.

Are industrial electric heaters available in the Kapiti region?

Yes. Several industrial electric heating solutions are available in the Kapiti region for both temporary and permanent installations.

Who provides industrial electrical and heat pump services in Kapiti?

Industrial electrical services in Kapiti are provided by companies such as:

- Brien Electrical Ltd

- Whittaker Electrical & Heat Pumps

- All Electrical & Heat Pumps

Where can businesses get quotes for industrial heating in Kapiti?

Local suppliers like Argus Heating and HEATME offer quotes and tailored industrial heating solutions.

Conclusion

Choosing the right types of electric heaters for industrial use in Kapiti is essential for ensuring efficient, safe, and cost-effective heating tailored to your facility’s unique needs. Whether you require fan-forced space heaters for quick air circulation, infrared heaters for targeted warmth, or immersion heaters for liquid heating, understanding the specific applications and Kapiti’s coastal environment will guide your decision.

Professional installation by qualified electricians ensures compliance with New Zealand’s electrical standards and maximizes the performance and longevity of your heating systems. Additionally, considering energy efficiency and regular maintenance, including servicing heat pumps annually, can significantly reduce energy consumption and operating costs.

For industrial facilities aiming to balance comfort, productivity, and sustainability, integrating advanced heating solutions such as heat pumps alongside traditional electric heaters offers a smart path forward. By making informed choices and working with trusted local suppliers and installers, Kapiti businesses can achieve reliable heating solutions that meet their operational demands while minimizing their carbon footprint and energy costs.